In heavy-duty engines, innovation, and efficiency drive the market forward. These powerhouses are the unsung heroes in various industries, from transportation to agriculture. This article takes a closer look at the intricate world of heavy-duty engines, highlighting their importance, the key components that keep them running smoothly, and maintenance tips to ensure their longevity and reliability.

The Backbone of Industry

Heavy-duty engines are more than just machinery; they are the backbone of numerous sectors. They power the trucks that deliver goods across countries, the tractors that plow thousands of acres, and the machinery that builds the infrastructure of our cities. Understanding these engines is crucial for anyone involved in these industries.

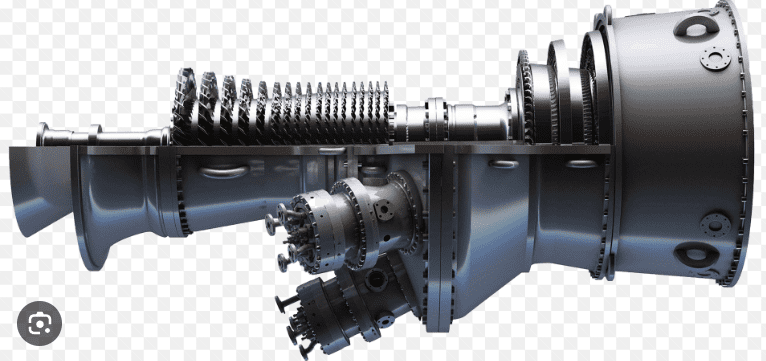

Essential Components of Heavy-Duty Engines

Several key components work together to ensure the smooth operation of these engines. Each part plays a vital role, and understanding these can help in proper maintenance and troubleshooting.

- Fuel System: The lifeline of the engine, ensuring a clean and constant fuel supply.

- Exhaust System: Responsible for safely expelling combustion gases.

- Cooling System: Maintains optimal operating temperatures and prevents overheating.

- Lubrication System: Minimizes friction and wear between moving parts.

The Cummins ISX Turbo, for instance, stands as a testament to the intricacy and power of these components, pushing the boundaries of efficiency and reliability.

The Role of Turbochargers

A pivotal component in many heavy-duty engines is the turbocharger. It’s a remarkable technology that enhances engine performance, fuel efficiency, and emission control. By compressing the air that enters the engine, turbochargers allow more fuel to be burned, thus increasing power output without increasing engine size.

Maintenance: Ensuring Longevity and Performance

Proper maintenance is the key to prolonging the life of heavy-duty engines and ensuring they operate at peak performance. Here are essential maintenance tips:

- Regular Oil Changes: Keeps the engine components well-lubricated and running smoothly.

- Air Filter Replacement: Ensures the engine “breathes” clean air, preventing damage from dirt and debris.

- Fuel System Maintenance: Keeps the fuel clean and the system free from clogs or leaks.

- Coolant Checks: Ensures the engine does not overheat and the cooling system is functioning correctly.

Importance of Using Quality Parts

Using high-quality parts like the Cummins ISX Turbo can significantly impact the performance and lifespan of heavy-duty engines. Quality parts ensure:

| Factor | Benefit of Quality Parts |

| Reliability | Decreases the likelihood of breakdowns and malfunctions. |

| Performance | Maximizes the engine’s power output and efficiency. |

| Longevity | Extends the life of the engine by reducing wear and tear. |

Navigating Challenges in Heavy-Duty Engine Management

Managing these engines comes with its set of challenges, from ensuring regular maintenance to staying updated with technological advancements. However, the benefits of proper engine management are clear: improved performance, reduced downtime, and significant cost savings in the long run.

Final Reflections

Exploring the world of heavy-duty engines reveals the complexity and importance of these industrial powerhouses. Understanding the key components, like the turbocharger, and adhering to a strict maintenance regimen ensures these engines continue to be the reliable backbone of various industries. Always remember, investing in quality parts and proper care is not an expense but a saving in the grand tapestry of industrial operations.